Scientist of the Day - Arthur Woolf

Arthur Woolf, an English mechanical engineer, died Oct. 16, 1837, at the age of about 71, having been born sometime in 1766. He came from and grew up in Cornwall, and journeyed to London when he was 19 to work for Joseph Bramah. He was employed by various firms in London before returning to Cornwall to work for Harvey & Co, which made steam engines for mines.

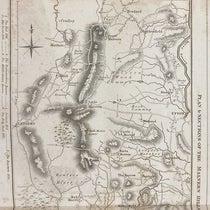

Cornwall was famous for its tin and copper mines. The mines were deep, which means that had lots of underground water that had to be pumped out. Water is heavy, and pumping it out of a deep mine can be expensive. The Newcomen engine had been invented expressly for pumping water out of mines, and it was cheap to run, but horribly inefficient. The Watt & Boulton steam engine, which had a separate condenser for the steam, so the main piston chamber could stay hot, was much more efficient. But it used up a lot of coal. The problem Cornish mines faced was that they had no native coal, so coal had to be imported, and was thus very expensive. Many mines, such as Consolidated Mines (Consols) had to close by the early 19th century because they had no affordable water removal system.

Woolf returned to Cornwall and went to work as chief engineer for John Harvey of Harvey & Co in Hayle, West Cornwall, which made engines for mines. Woolf invented a new kind of steam engine, which used high-pressure steam (the Newcomen engine worked at atmospheric pressure; the Watt engine used low-pressure steam). Woolf may have profited from the work of Richard Trevithick, a fellow Cornishman, five years younger, who began building high-pressure steam engines for use in locomotives about this time. The Woolf engine was a compound engine, meaning that it used high-pressure steam to operate one piston, and then used the exhausted steam, which still had considerable residual pressure, to operate a conventional Watt-style engine. The resulting compound engine came to be called a Cornish engine, and it saved the Cornish mining industry. Consols reopened in 1819, using Woolf engines, and they were a great success. Some of them had pistons with diameters of 90 inches or more, which made them very powerful. And they were efficient to operate.

For the non-engineer, the most obvious feature of the Woolf Cornish engine is that it is impressively attractive. That is probably why so many have been preserved in mining museums around the world, such as the Abbey Pumping Station in Leicester and the London Museum of Water and Steam (third image). People just love to look at them, and that would include me. We show photos of several restored Woolf Cornish engines with this post.

Just after the death of Woolf, the Dutch government ordered three Woolf compound beam engines from Harvey & Co, to drain the Haarlemmermeer, “Haarlem’s lake.” The engine built for the Cruquius pumping station was the largest Woolf steam engine ever constructed. It can still be seen at the Museum De Cruquius in the Netherlands, in the municipality of Haarlemmermeer, which arose where the lake used to be (fourth image). Notice the beams protruding from the pump-house walls.

There is one biography of Woolf, by T. R. Harris, Arthur Woolf: The Cornish Engineer 1766-1837 (Bradford Barton Ltd., 1966). I am sorry to say our library does not own this book, which made writing this post a bit difficult. It is also a shame that we have no portrait of Woolf. So it is very nice that we have so many of his Cornish engines to remember him by.

William B. Ashworth, Jr., Consultant for the History of Science, Linda Hall Library and Associate Professor emeritus, Department of History, University of Missouri-Kansas City. Comments or corrections are welcome; please direct to ashworthw@umkc.edu.